Cable Stay Bridge Inspections Get A New Robot

- Doug Thaler

- Apr 22, 2017

- 3 min read

The US infrastructure is deteriorating and budgets

are being diverted and reduced everyday. The task of maintaining the infrastructure for many countries including the US has became a challenge. With limited assets and archaic inspection methods, how do you manage your maintenance. How do you even know what needs maintaining. After a long study of the industry and their inspection methods, it became clear that the subjective testing being conducted today was inadequate for identifying & repairing issues related to our Infrastructure. Infrastructure Preservation Corporation, "IPC" developed specific infrastructure inspection services to help the Department Of Transportation/asset owners better allocate their budgets through inspections. These inspections are more quantitative than current manual subjective inspections and at the same time safer for the inspector and less burdensome for the public (fewer lane closures).

IPC’s patented robotics are a game changer in making infrastructure safer and less costly to maintain. One of IPC’s robotic services CableScan® is a robotic inspection that inspects the external cables of cable stay bridges. IPC’s inspection service does not require lane closures or bucket trucks to be parked on the bridge. Their inspection robot is portable, wireless and is controlled from a ground station. It can be steered around obstructions and has multiple redundancies such as rollover backup batteries and an automatic return to base in the event of a power failure. One cannot compare IPC's robotic Bridge inspection or high mast light pole inspection services PoleScan® to that of current day manual inspections. There is just no match for the technology IPC provides.

Infrastructure Preservation Corporation, “IPC” has developed robotic technology that is quickly replacing the manual Cable Stay Bridge Inspection services conducted today.

IPC bridge inspection services provide asset managers (department of transportation) with quantitative data unlike anything they have seen to date. Quantitative data will allow the Department Of Transportation to properly allocate their limited maintenance dollars in a much more efficient manner. By locating early stage deterioration and properly maintaining & conducting repairs in order of severity, the service life of our critical infrastructure assets can be extended and untimely replacements avoided, saving billions in infrastructure costs.

CableScan® provides a 360 degree inspection of Cable stays with no lane closures or boom trucks. . It records high definition video and stills of the cable, seams, grout ports, saddle and more. All issues are recorded and photographed as well as the position along the stay and deck. LIDAR is used to measure the length and width of cracks. The device is wirelessly controlled from a ground station and can steer around obstructions (grout ports).

No lane closures or bucket trucks are required. Inspections can take place during the day with no danger to the inspector or the public.

Current Inspection IPC’s CableScan® -Cable Stay Inspection

CableScan®-R is a repair bot that can make specific minor repairs without lane closures or boom trucks

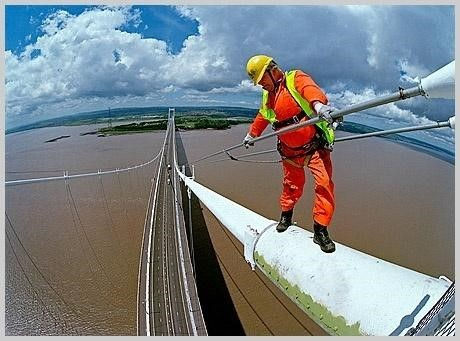

Currently inspections require lane closures and bucket trucks or inspectors that climb the stays. A man visually inspects what he can see. During the last manual inspection of 84 cable stays on one bridge, the engineering company found 1 problem. IPC was asked to QC the inspection that used traditional methods. IPC located 12 issues on just 9 of the 84 stays. During the inspection with the traditional method with lane closures there were 9 accidents that occurred over the six week period.

In the US and Canadian markets, Infrastructure Preservation Corporation, "IPC" is the service company and conducts bridge inspections directly. Internationally, IPC we license our technology to strategic partners.

Infrastructure Preservation Corporation, “IPC” is a professional services bridge inspection and robotic engineering company advancing infrastructure inspections worldwide. For more information on IPC’s services contact: Doug Thaler at info@infrastructurepc.com.

Comments